Fixed denture

Internal Defects

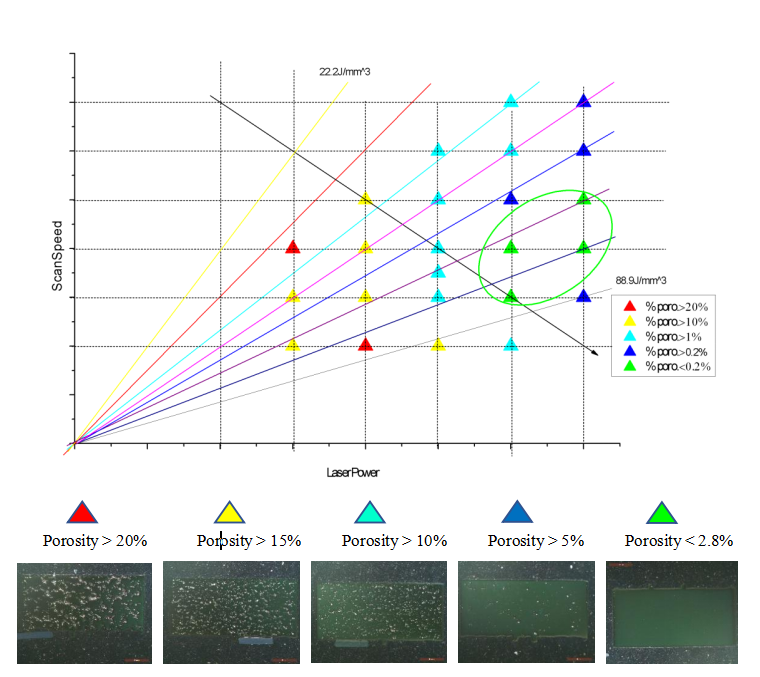

Internal defects of 3D printing, such as porosity, lack of fusion and cracks, are often produced during selective laser melting (SLM) process by inappropriate parameters. All these defects will adversely affect the performance of final parts: tooth crown, bridge and removable partial denture. Addressing the defects, our technical team optimized the whole process in terms of laser energy density, which relates all critical SLM process parameters. From elimination of porosity point of view, shown in the following picture, the best process window was found by optimizing laser scan speed and power.

Best process window to eliminate porosity

Deformation Control

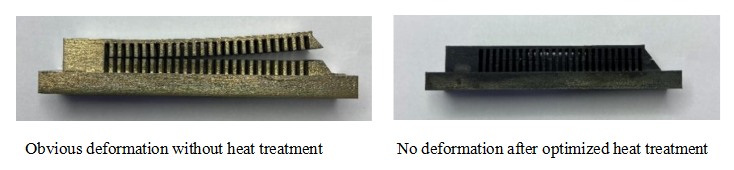

Deformation of dental parts is often found after 3D printing process and heat treatment, but can be well controlled by optimizing printing process and design of supports. As for heat treatment, our technical team developed the best heat treatment conditions for printed parts.

SLM process simulation based on finite element analysis shows the quantitative deformation and stress distribution. The possible process parameters were fine-tuned and then verified by both process simulation and real printing, in order to introduce our metal powders successfully.

Fitness

Fitness is very critical to evaluate the quality of 3D-printed metal crown, bridge and removable partial denture. Our technical team has finished a series of experiments to achieve the best fit of printed parts made of DPR metal powders. The result shows the fitness are very competitive to the products from top brand suppliers.

Schematic diagram of tightness test

Results of the fitness test

Test conditions | Test group | Control group 1 | Control group 2 |

DPR-M01 Printed parts | Imported cobalt chromium alloy castings | Imported powder printed parts |

Test temperature | Room temperature | Room temperature | Room temperature |

Specimen condition | Stress-relief annealed state (750℃×1h) | Original cast state | Heat treatment by the manufacturer |

Number of samples per group | 5 | 3 | 3 |

Test results | Good | Good | Good |